A Straight Path to Reliable Production

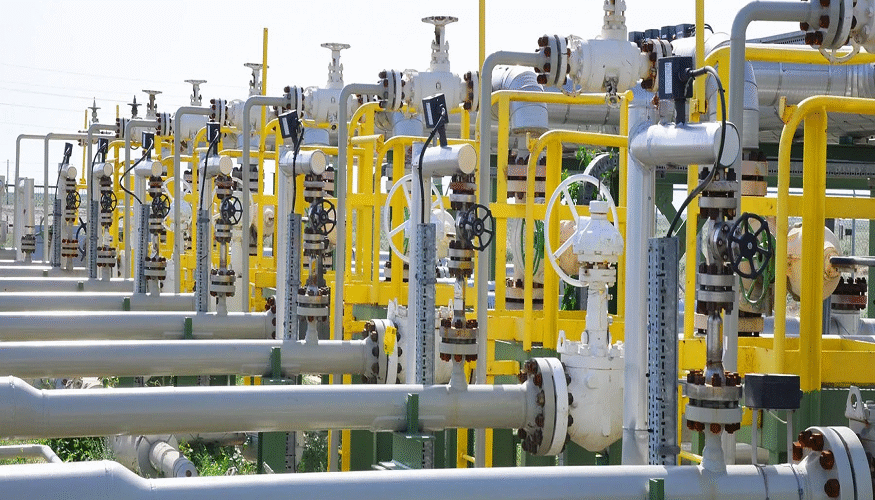

Keeping oil and gas output steady isn’t about flashy tech or guesswork—it’s about steady hands on the controls every single day. That’s why more producers are turning to Oil and Gas Contract Operating Services as a core part of their strategy. Instead of stretching an in-house crew to cover every well, they bring in teams whose only job is to keep operations running safely and efficiently. These specialists arrive with their own systems, seasoned staff, and proven routines, ready to handle the daily grind without slowing your long-term goals.

The benefit shows up fast: fewer shutdowns, cleaner compliance, and a budget that stays predictable. For companies chasing consistent barrels and fewer surprises, contract operators offer something rare in this industry—calm, repeatable results. This isn’t outsourcing for convenience; it’s a practical move that protects both production and profit when markets shift or equipment wears thin.

How To Spot a Quality Operator

Choosing the right partner starts long before any signatures. First, list every task you expect—from maintenance to reporting—so nothing is missed. Meet candidates on-site, not just over a call, and watch how they interact with crews. Request detailed safety statistics and specific examples of past challenges. A strong operator explains how they train people, manage gear, and stay compliant with local rules. Review their crisis plans; the quiet details reveal a lot. And don’t skip the finance talk—transparent billing and precise cost controls separate professionals from pretenders.

- Visit active job sites to see their culture.

- Demand a written safety and emergency plan.

- Check references beyond what they provide.

What Daily Work Should Look Like

Once they’re hired, daily habits tell the real story. Reliable operators start with toolbox talks before each shift. They check the equipment before any crew member climbs a ladder. They send short, clear reports every day so you know production levels and issues fast. They follow a tight maintenance schedule and adjust when weather or demand changes. They keep spare parts handy to avoid downtime. Good operators also keep regulators updated without you chasing them for paperwork. If you’re not seeing this steady rhythm within a week, something’s off.

- Expect a morning briefing and an evening recap.

- Require real-time data on production and downtime.

- Watch for proactive maintenance, not just repairs.

Why Monitoring Protects Your Bottom Line

Monitoring isn’t just a tech buzzword—it’s your early warning system. Sensors and simple dashboards reveal leaks, pressure drops, and wear before they turn costly. Operators who use these tools can schedule maintenance during slow periods instead of emergency shutdowns. They also help you plan inventory and staffing. Data trends show which wells need upgrades or which equipment is near retirement. And when regulators or investors ask for proof, you have clean records ready.

- Use live dashboards to catch problems early.

- Track trends to predict maintenance needs.

- Share accurate reports with investors and agencies.

Next Steps for a Smooth Partnership

Bringing in contract operators is more than outsourcing—it’s a partnership. Set clear goals and hold regular check-ins to prevent minor issues from escalating. Review reports together and adjust plans as needed. Establish a feedback loop to help them understand your priorities and for you to learn from their field experience. With the proper structure, you maintain control over results while allowing experts to handle the daily grind. That’s the balance that keeps production steady and budgets healthy. If steady output and fewer sleepless nights sound good, start by drafting a scope of work today and talk to proven operators tomorrow.